In today's interconnected world, electronics have become an integral part of our daily lives. From smartphones to laptops, televisions to smart home devices, the demand for electronics is ever-increasing. However, have you ever wondered where these electronic devices are manufactured? In this blog post, we will delve into the global landscape of electronics manufacturing, exploring the key locations, trends, and factors that shape this industry.

- The Rise of Asia as the Manufacturing Hub:

Over the past few decades, Asia has emerged as the dominant player in electronics manufacturing. Countries like China, Taiwan, South Korea, and Japan have established themselves as major manufacturing hubs. The availability of skilled labor, cost-effectiveness, and supportive infrastructure have contributed to their success. China, in particular, has become the world's largest electronics manufacturer, producing a significant portion of the global supply. - The Role of Contract Manufacturers:

In the electronics industry, many companies outsource their manufacturing processes to contract manufacturers. These specialized firms handle the production, assembly, and testing of electronic components and devices on behalf of the original equipment manufacturers (OEMs). Contract manufacturers are often located in regions with favorable business environments, such as Southeast Asia, Eastern Europe, and Mexico. - Shifting Dynamics: The Impact of Trade Wars and Geopolitical Factors:

The electronics manufacturing landscape is not immune to geopolitical tensions and trade disputes. Recent trade wars between the United States and China, for example, have led to uncertainties and disruptions in the supply chain. As a result, some companies have started diversifying their manufacturing locations to mitigate risks. Countries like Vietnam, Thailand, and Malaysia have witnessed an increase in electronics manufacturing investments as businesses seek alternative production bases. - The Importance of Supply Chain Management:

Efficient supply chain management is crucial in the electronics manufacturing industry. Companies need to ensure a steady flow of raw materials, components, and finished products across multiple locations. Just-in-time manufacturing and lean production techniques are commonly employed to optimize efficiency and reduce costs. Additionally, advancements in logistics and transportation have facilitated the seamless movement of goods across borders. - The Role of Automation and Industry 4.0:

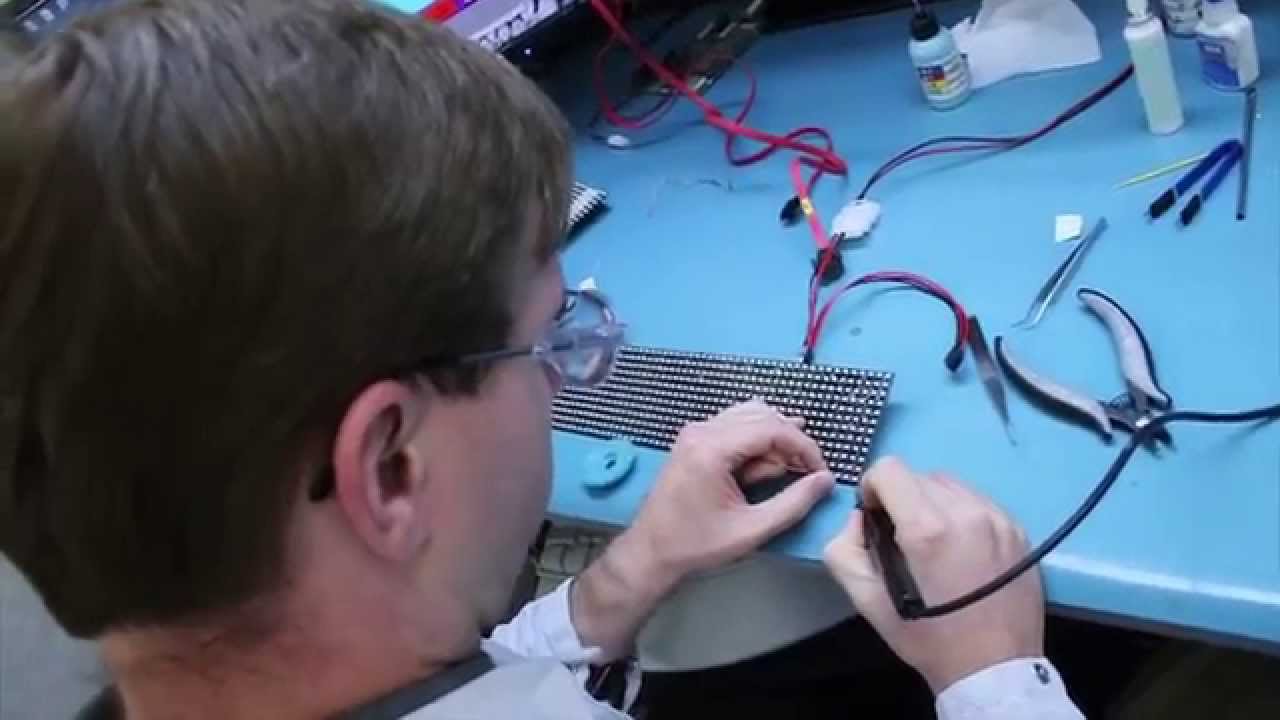

The advent of Industry 4.0 technologies, such as robotics, artificial intelligence, and the Internet of Things (IoT), is revolutionizing electronics manufacturing. Automation is increasingly replacing manual labor in repetitive tasks, leading to improved productivity and quality control. Smart factories equipped with interconnected systems enable real-time monitoring, predictive maintenance, and data-driven decision-making.

Conclusion:

The global landscape of electronics manufacturing is dynamic and constantly evolving. Asia, particularly China, continues to dominate the industry, but geopolitical factors and technological advancements are reshaping the manufacturing map. As consumers, it is essential to understand the origins of our electronic devices and the complex supply chains behind them. By staying informed about the latest trends and developments, we can make more informed choices and support sustainable and responsible manufacturing practices.