In the world of electronics, ensuring the smooth operation of devices and systems is of utmost importance. One crucial aspect that plays a significant role in achieving this is Electromagnetic Compatibility (EMC). In this blog post, we will delve into the depths of EMC, exploring its significance, principles, and practical applications.

- Understanding EMC:

Electromagnetic Compatibility refers to the ability of electronic devices and systems to function properly in their intended electromagnetic environment without causing or experiencing interference. It encompasses two key aspects: emission and immunity. Emission refers to the unintentional release of electromagnetic energy, while immunity refers to the ability to withstand external electromagnetic disturbances. - Importance of EMC:

In today's interconnected world, where electronic devices are ubiquitous, EMC is vital to ensure the reliable operation of various systems. Failure to comply with EMC standards can lead to malfunctions, data corruption, and even safety hazards. By adhering to EMC principles, manufacturers can enhance product quality, minimize risks, and meet regulatory requirements. - EMC Standards and Regulations:

To ensure EMC compliance, various international organizations, such as the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC), have established standards and regulations. These standards define limits for electromagnetic emissions and specify immunity levels for different environments. Compliance with these standards is crucial for manufacturers to obtain certifications and market their products globally. - EMC Design Considerations:

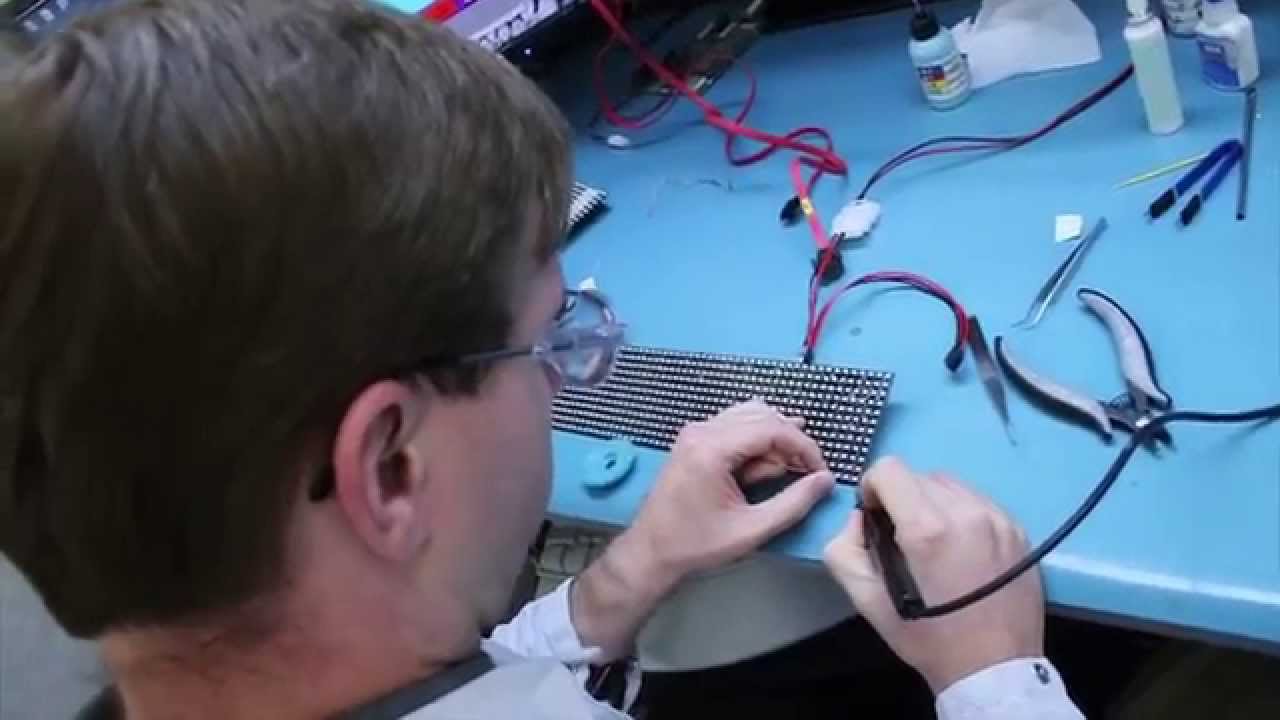

Designing electronic devices with EMC in mind is essential to minimize interference and ensure optimal performance. Key considerations include proper grounding and shielding techniques, careful component placement, and effective filtering of electromagnetic emissions. Additionally, the use of specialized materials and techniques, such as ferrite beads and differential signaling, can further enhance EMC performance. - EMC Testing and Evaluation:

Before bringing electronic products to market, thorough EMC testing and evaluation are necessary. This involves subjecting devices to various electromagnetic environments and assessing their emission and immunity characteristics. Testing methods may include radiated and conducted emissions testing, electrostatic discharge (ESD) testing, and susceptibility testing. Identifying and rectifying any EMC issues during the testing phase is crucial to avoid costly recalls and customer dissatisfaction. - EMC in Specific Industries:

EMC considerations vary across different industries. For example, in the automotive sector, EMC is crucial to ensure the reliable operation of electronic systems in the presence of high-voltage components and electromagnetic interference from other vehicles. Similarly, in the medical field, EMC plays a vital role in guaranteeing the safe operation of medical devices in the presence of other electronic equipment.

Conclusion:

Electromagnetic Compatibility is a critical aspect of electronics that ensures the seamless operation of devices and systems in today's interconnected world. By understanding the principles of EMC, adhering to standards, and implementing proper design considerations, manufacturers can create reliable and compliant products. By doing so, they not only meet regulatory requirements but also enhance customer satisfaction and maintain a competitive edge in the market.