Electrical transformers are an integral part of our modern power systems, enabling the efficient transmission and distribution of electricity. Understanding how these complex devices work is crucial for engineers, technicians, and anyone interested in the field of electrical engineering. In this comprehensive guide, we will delve into the inner workings of electrical transformers, exploring their principles, components, and applications.

- The Basics of Electrical Transformers:

To comprehend the intricacies of electrical transformers, we must first grasp their fundamental principles. Transformers operate on the principles of electromagnetic induction, which involves the transfer of energy between two or more coils of wire. The primary coil, connected to an alternating current (AC) power source, induces a varying magnetic field. This magnetic field, in turn, induces a voltage in the secondary coil, allowing for the transformation of electrical energy. - Core and Windings:

The core and windings are vital components of electrical transformers. The core, typically made of laminated iron or steel, provides a low-reluctance path for the magnetic flux generated by the primary coil. This ensures efficient energy transfer. The windings, consisting of insulated copper or aluminum wire, are wound around the core. The primary winding receives the input voltage, while the secondary winding delivers the transformed output voltage. - Turns Ratio and Voltage Transformation:

The turns ratio between the primary and secondary windings determines the voltage transformation in a transformer. By altering the number of turns in each winding, transformers can step up or step down the voltage levels. Step-up transformers increase the voltage, while step-down transformers decrease it. This ability to modify voltage levels is crucial for long-distance power transmission and local distribution. - Transformer Efficiency and Losses:

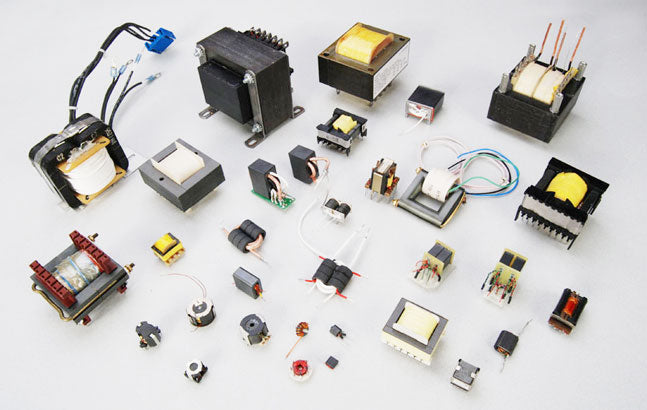

Efficiency is a critical factor in transformer design and operation. Transformers aim to minimize energy losses during the transformation process. Various types of losses occur, including copper losses (due to resistance in the windings), core losses (hysteresis and eddy currents), and stray losses (leakage flux). Design considerations, such as selecting appropriate core materials and optimizing winding configurations, help enhance transformer efficiency. - Types of Transformers:

Transformers come in various types, each designed for specific applications. Power transformers are used in electrical grids for high-voltage transmission and distribution. Distribution transformers deliver electricity to homes and businesses at lower voltage levels. Instrument transformers are employed for measuring and protecting electrical systems. Autotransformers offer voltage transformation with a single winding, while isolation transformers provide electrical isolation and safety. - Transformer Cooling and Maintenance:

Efficient cooling is crucial for transformer operation, as excessive heat can degrade performance and shorten its lifespan. Transformers employ various cooling methods, including air cooling, oil cooling, and liquid immersion cooling. Regular maintenance, including inspections, oil testing, and preventive measures, ensures optimal transformer performance and longevity.

Conclusion:

Electrical transformers play a vital role in our power infrastructure, enabling the efficient transmission and distribution of electricity. By understanding the principles, components, and applications of transformers, we gain insights into their inner workings. This comprehensive guide has explored the basics of transformers, voltage transformation, efficiency, types, cooling, and maintenance. Armed with this knowledge, engineers and enthusiasts can appreciate the remarkable technology behind electrical transformers.