When it comes to manufacturing complex and intricate parts, high precision is a non-negotiable requirement. For industries such as aerospace, automotive, medical devices, and electronics, the need for high-quality, meticulously crafted components is paramount. In this blog post,As a professional manufacturer, Vibo will share the importance of choosing the right high precision CNC milling parts factory. Vibo uses advanced computer numerical control (CNC) machines to produce parts with exceptional precision, ensuring that each component meets strict industry standards.

Why High Precision CNC Milling Matters?

Precision in manufacturing is more than just a luxury - it's a necessity. In industries like aerospace or medical device manufacturing, even the slightest variation in a part can have serious consequences. A small deviation from the required specifications can result in product failure, safety risks, and financial losses. Here are some reasons why high precision CNC milling is vital:

1. Quality Assurance: High precision CNC milling ensures that each part produced is consistent in quality. Whether you're producing hundreds or thousands of parts, you can trust that they will meet the same high standards.

2. Cost-Efficiency: While high precision milling may require a more significant upfront investment in specialized machines, it ultimately saves money in the long run. Parts that meet exact specifications reduce the likelihood of defects and costly rework.

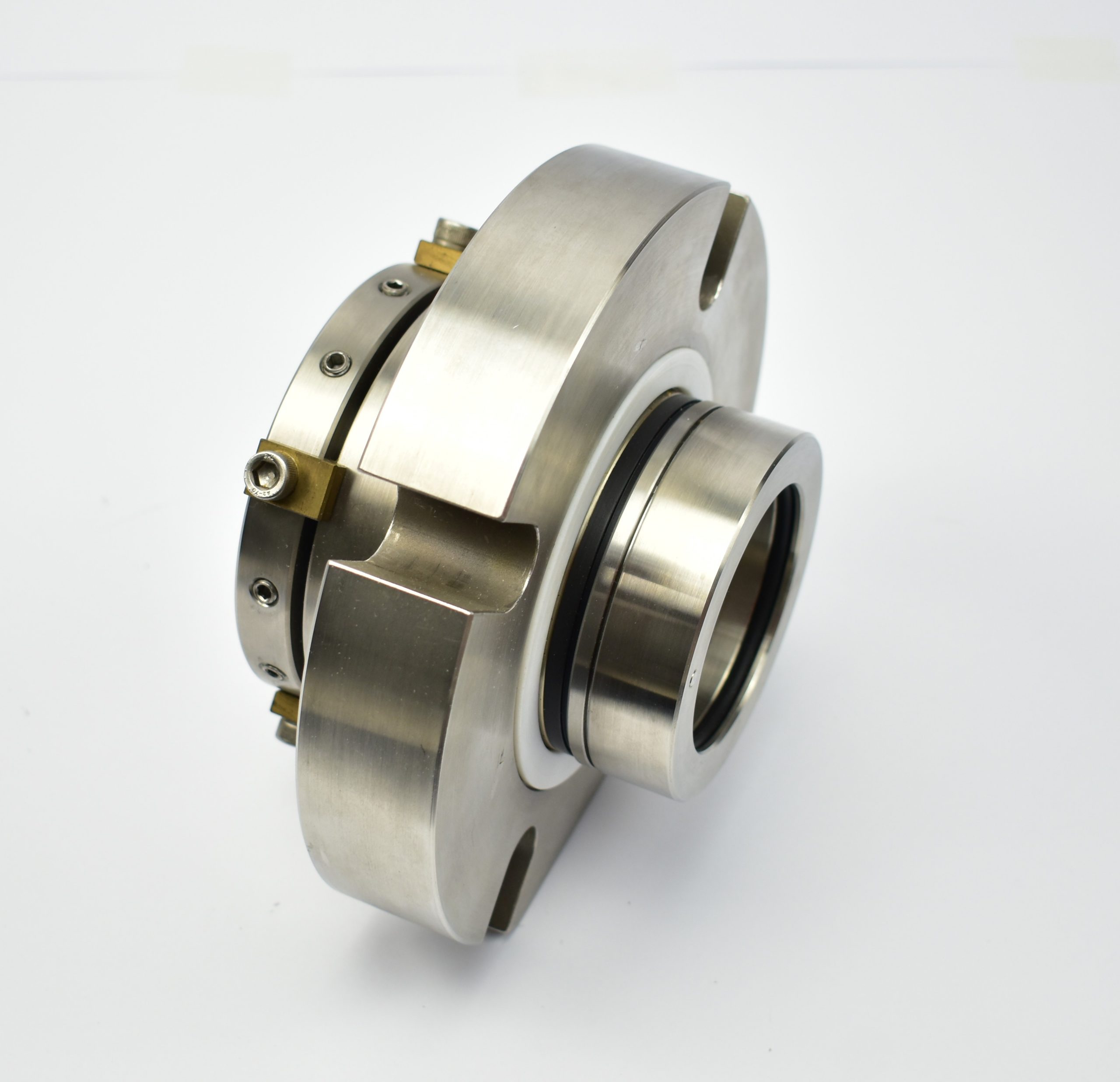

3. Complex Geometries: Many industries require parts with intricate shapes and tight tolerances that cannot be achieved using traditional manufacturing methods. High precision CNC milling is ideal for creating such complex geometries with ease and accuracy.

4. Speed and Efficiency: CNC milling machines operate at high speeds, making them faster than manual methods while maintaining high precision. This is especially important for industries that require high-volume production runs.

How to Choose High Precision CNC Milling Parts Factory?

Selecting the right high precision CNC milling parts factory is a critical decision that can impact the overall success of your manufacturing operations. Here are some factors to consider before making your choice:

1. Experience and Expertise

Look for a factory with years of experience in producing high-precision CNC milled parts. A well-established factory is more likely to have the necessary skills, knowledge, and equipment to meet your specific requirements. Additionally, consider the factory' s expertise in your industry. If you' re in the aerospace sector, for example, you' ll want a manufacturer with experience in producing complex, lightweight components.

2. Technology and Equipment

CNC milling technology has advanced significantly over the years. High-precision factories should use state-of-the-art machines that offer the latest advancements in speed, accuracy, and material handling. Multi-axis CNC machines, for example, are capable of machining parts from multiple angles in a single setup, ensuring higher precision and reducing the need for secondary operations.

3. Quality Control Processes

A reputable high precision CNC milling parts factory should have robust quality control measures in place. This includes regular inspections, testing, and calibration of machines to ensure that parts meet the required tolerances. Ask the factory about their quality assurance process and whether they have certifications such as ISO 9001, which is a global standard for quality management.

4. Material Capabilities

The ability to work with a wide variety of materials is essential for a high precision CNC milling parts factory. Depending on your project, you may require parts made from exotic alloys, stainless steel, aluminum, or advanced polymers. A factory with diverse material capabilities can help you achieve your desired results without compromising on quality.

5. Lead Time and Flexibility

Efficiency and lead times are key considerations when selecting a CNC milling factory. If you need parts delivered quickly, a factory with a streamlined workflow and flexible scheduling can be a game-changer. Additionally, it' s important to evaluate the factory' s ability to scale production up or down based on your requirements.

6. Cost and Value

While cost is an important consideration, it should not be the sole factor in your decision. A factory that offers the lowest price may compromise on quality, which can result in long-term costs due to defects and rework. Instead, focus on value: what you are getting in terms of quality, precision, and customer service for the price.

Benefits of High Precision CNC Milling Parts Factory

When you choose the right high precision CNC milling parts factory, you' re investing in the long-term success of your business. Here are some of the benefits:

- Reliable Supply Chain: A trusted CNC milling factory will ensure consistent, on-time delivery of high-quality parts, helping you maintain a reliable supply chain.

- Custom Solutions: Whether you need a single prototype or a large batch of components, high precision CNC milling factories can offer tailored solutions to meet your needs.

- Reduced Risk of Errors: The advanced technology and quality control systems in place at high precision CNC milling factories minimize the risk of defects and errors, resulting in fewer production delays and lower costs.

- Innovation and Collaboration: A good CNC milling parts factory will not only produce parts to specification but will also collaborate with you to optimize designs, suggest material alternatives, and help you achieve your manufacturing goals.

Conclusion

Choosing the right high precision CNC milling parts factory is a vital decision for any business involved in the production of complex components. By selecting a factory that meets your specific needs for quality, experience, technology, and customer service, you can ensure that your parts are manufactured with the precision required to meet the most stringent industry standards. With the right factory partnership, you can reduce costs, improve product quality, and bring your products to market faster.

www.viboprecision.com

Vibo