Mechanical seals are critical components used in various industrial applications to prevent leakage of fluids and gases. They are designed to withstand high pressures, temperatures, and corrosive environments. In this article, we will explore the different types of mechanical seals, their applications, and maintenance requirements.

Types of Mechanical Seals:

- Pusher Seals: These seals use a spring-loaded mechanism to maintain contact between the seal faces. They are commonly used in applications with low to medium pressures and temperatures.

- Non-Pusher Seals: These seals do not use a spring-loaded mechanism and rely on the pressure of the fluid to maintain contact between the seal faces. They are commonly used in applications with high pressures and temperatures.

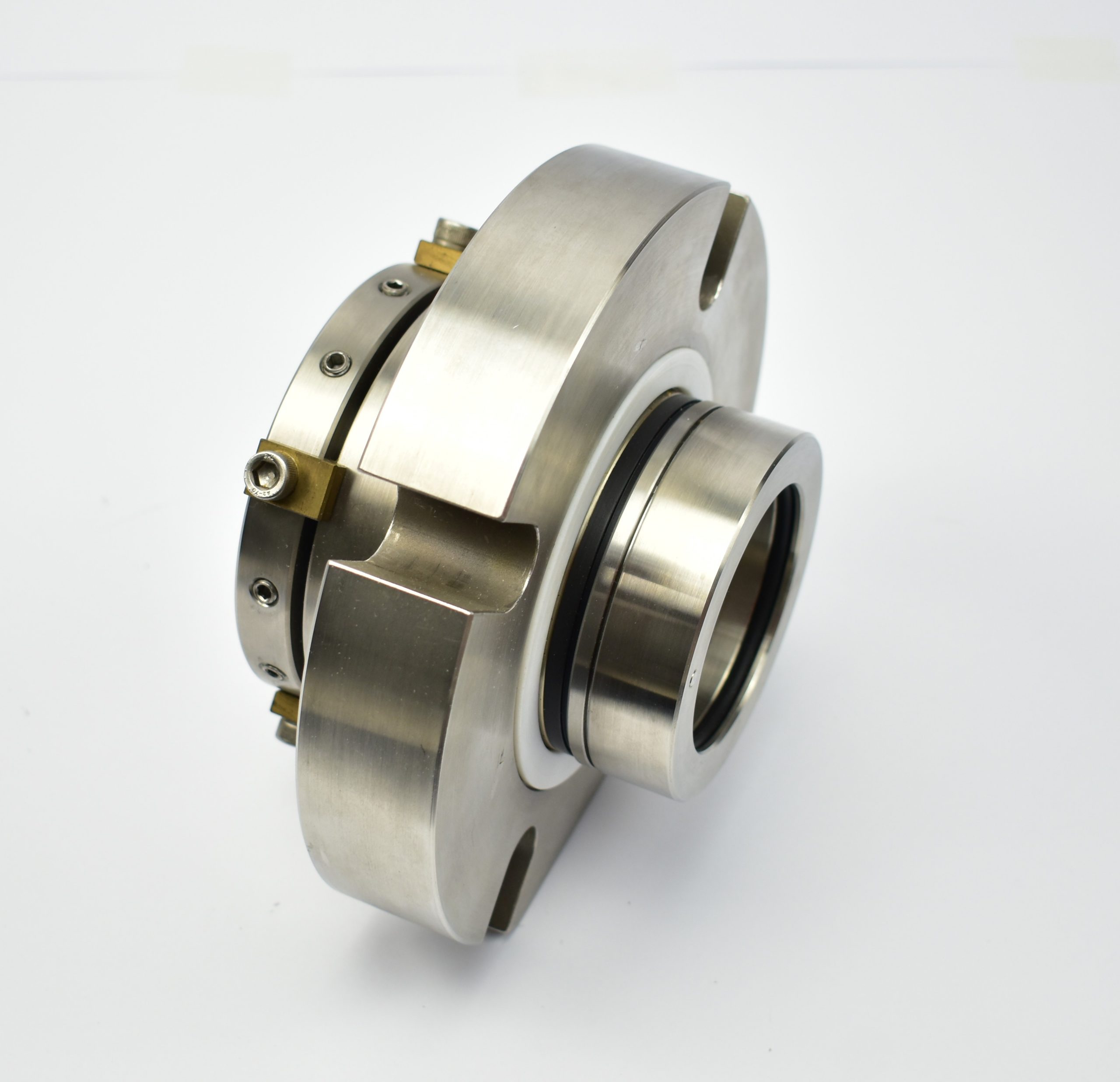

- Cartridge Seals: These seals are pre-assembled and can be easily replaced without disassembling the equipment. They are commonly used in applications with high pressures and temperatures and where maintenance downtime is critical.

- Split Seals: These seals are designed to be installed without disassembling the equipment. They are commonly used in applications where the shaft cannot be removed or where the equipment cannot be disassembled.

Applications of Mechanical Seals:

Mechanical seals are used in various industrial applications, including:

- Pumps: Mechanical seals are used in centrifugal pumps, positive displacement pumps, and other types of pumps to prevent leakage of fluids.

- Compressors: Mechanical seals are used in reciprocating and centrifugal compressors to prevent leakage of gases.

- Mixers: Mechanical seals are used in mixers to prevent leakage of fluids and to maintain the integrity of the mixing process.

- Agitators: Mechanical seals are used in agitators to prevent leakage of fluids and to maintain the integrity of the mixing process.

- Reactors: Mechanical seals are used in reactors to prevent leakage of fluids and to maintain the integrity of the reaction process.

Maintenance of Mechanical Seals:

Proper maintenance of mechanical seals is critical to ensure their longevity and prevent leakage. Some maintenance tips include:

- Regular inspection of the seal faces for wear and damage.

- Proper lubrication of the seal faces to prevent dry running and overheating.

- Proper alignment of the equipment to prevent excessive vibration and misalignment.

- Proper installation of the seal to prevent damage during installation.

- Regular replacement of the seal to prevent failure and leakage.

Conclusion:

Mechanical seals are critical components used in various industrial applications to prevent leakage of fluids and gases. Understanding the different types of mechanical seals, their applications, and maintenance requirements is essential to ensure their longevity and prevent leakage. Proper maintenance of mechanical seals can help prevent costly downtime and equipment damage.